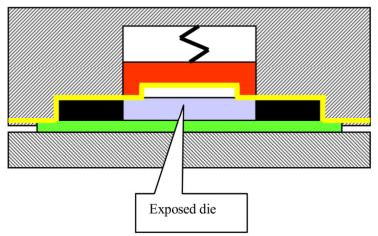

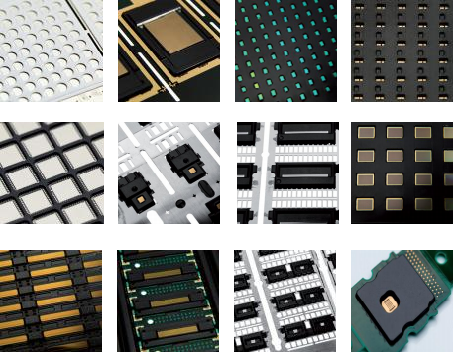

OpenMolding packaging is the opening window packaging, the packaging material is the same as the LGA packaging, the packaging process is different because OpenMolding packaging can protect the chip welding line while the chip perception area is completely exposed, while the LGA packaging is covered by molding material. Therefore, the fingerprint identification chip packaged by OpenMolding has better perception sensitivity while possessing high reliability of LGA, and the fingerprint pattern is clearer and complete.

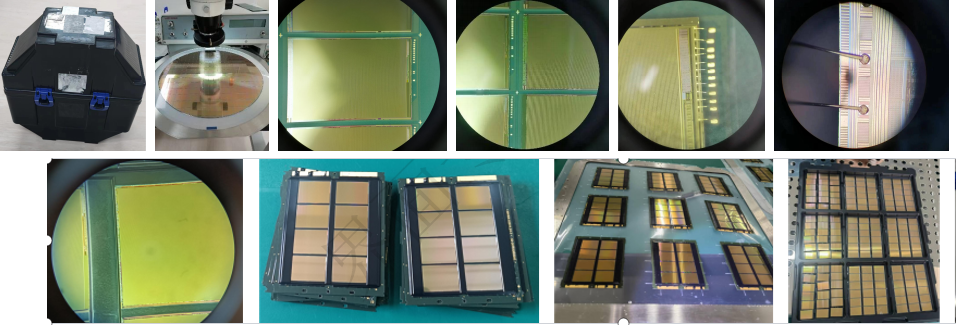

Window encapsulation (Open Molding) auxiliary encapsulation technology and system integration technology membrane (FilmAssistedMoldingTechnology, FAM) on the mould of double membrane and pneumatic dynamic auxiliary plug-in unique innovative design, Open the window and the cavity structure can be accomplished, It is suitable for the sensor chip package that needs to interact with the external environment, and on this basis, the sensor module system integration is realized.

OpenMolding packaging process needs to mold and protect the weak bonding line while exposing the chip perception area. Compared to traditional packaging technology, the chip design needs to fully consider the position relationship between the chip solder plate and the showing sense map area at the beginning of the chip design. In order to ensure that the OpenMolding process requirements are met while improving the wafer utilization as much as possible, the packaging design needs to specifically design the matching molding mold for the chip. In terms of packaging process, in addition to demanding DieBond position accuracy, the corresponding MoldReleaseFilm and molding process parameters need to be specifically matched. Ensure that the chip is not damaged at the same time, there can be no bubble/plastic seal clamp broken, and there can be no abnormal overflow in the chip perception area.